Imagine, for a moment, the heart of your Yanmar engine, a mighty 3-cylinder powerhouse that propels your boat, tractor, or generator. Deep within this mechanical marvel lies a crucial component: the injector pump. This unassuming piece is responsible for precisely measuring and delivering fuel to each cylinder, orchestrating the combustion that gives your engine its lifeblood.

Image: wiringfixarmani77.z19.web.core.windows.net

Unraveling the intricacies of the Yanmar injector pump can feel like deciphering a cryptic code, but fear not! This in-depth guide will illuminate the inner workings of this critical component, providing a visual roadmap through its complex anatomy. With a comprehensive understanding of the injector pump, you’ll be empowered to diagnose potential issues, troubleshoot performance problems, and ensure your Yanmar engine runs like a well-oiled machine.

The Heart of the Diesel Engine: Understanding the Injector Pump

At the core of every diesel engine lies the injector pump, a mechanical maestro that orchestrates the delicate dance of fuel injection. Unlike gasoline engines, where fuel is ignited by a spark plug, diesel engines rely on the heat generated by compressing air to ignite the fuel. This process requires precise fuel delivery, and that’s where the injector pump comes in. It acts as the engine’s fuel metering system, meticulously measuring and injecting fuel into the combustion chamber at just the right time and pressure.

In the case of a 3-cylinder Yanmar engine, the injector pump is specifically designed to meet the unique requirements of this powerplant. It’s a compact, yet robust system that delivers fuel to each cylinder with exceptional accuracy, playing a critical role in achieving optimal engine performance, efficiency, and longevity.

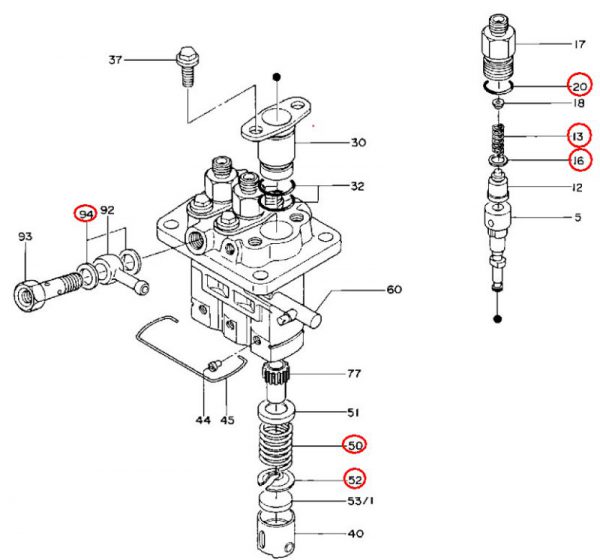

A Visual Journey into the 3-Cylinder Yanmar Injector Pump Diagram

To truly appreciate the complexities of the injector pump, a visual journey is essential. Let’s delve into a comprehensive diagram, breaking down its key components and functions:

1. The Pump Housing:

This robust casing houses the heart of the injector pump, shielding its internal components from the elements and providing a solid foundation for its operation.

2. The Plunger:

Think of the plunger as the engine’s fuel master, responsible for drawing fuel from the tank and pressurizing it before injection. It’s a piston-like component that moves within the pump housing, driven by precisely engineered cam lobes.

3. The Delivery Valve:

The delivery valve is the gatekeeper of fuel, ensuring it’s released into the cylinders at the precise moment for optimal combustion. Its spring-loaded design allows it to open under pressure, releasing a controlled amount of fuel into the injectors.

4. The Injector:

Positioned at the heart of each cylinder, the injector is the final destination for the fuel, delivering a measured spray into the combustion chamber at precisely the right moment.

5. The Fuel Lines:

These are the arteries of the fuel system, carrying pressurized fuel from the pump to each individual injector.

6. The Governor:

This crucial component ensures that the engine operates at a consistent speed, regardless of fluctuations in load. It monitors engine RPM and adjusts the fuel flow accordingly, maintaining smooth and efficient operation.

The Science Behind the Injection: Plunger Rotation and Fuel Delivery

The intricacies of the Yanmar injector pump diagram come to life when we understand the interplay between these components. As the engine crankshaft rotates, the camshaft turns, driving the plunger. This precise motion draws fuel from the tank, building pressure within the pump housing.

When the plunger reaches its peak, the delivery valve opens, releasing the pressurized fuel into the injectors. The timing of this release is critical, as it directly impacts the combustion process. A precise injection sequence ensures optimal performance and minimizes emissions.

Image: injectionpumps.co.uk

Decoding the Yanmar Injector Pump Diagram: A Practical Guide

Now that we’ve established a foundational understanding of the injector pump’s components and functions, let’s translate this knowledge into practical insights.

1. Diagnosing Engine Problems:

The injector pump is a critical component, and any malfunctions can lead to a range of engine problems, including:

- Difficulty starting: A faulty pump may be unable to deliver enough fuel to initiate combustion.

- Stalling: Irregular fuel delivery can cause the engine to sputter and stall.

- Rough idling: Inconsistent fuel injection can result in uneven combustion and a rough idle.

- Reduced power: If the pump isn’t delivering enough fuel, you’ll experience a noticeable loss of power.

- Increased fuel consumption: Malfunctions in the pump can lead to inefficient fuel consumption.

2. Maintaining a Healthy Injector Pump:

Maintaining your injector pump is crucial to ensure smooth and reliable engine performance. Here are a few key steps:

- Regular fuel filter changes: Fuel contaminants can damage the sensitive components of the injector pump. Change the fuel filter regularly according to the manufacturer’s recommendations.

- Use high-quality fuel: Avoid using low-grade fuel or fuel that may contain contaminants.

- Monitor engine oil level: Low oil levels can cause damage to the engine, including the injector pump.

- Regular inspection: Periodically check for any signs of wear or leaks in the injector pump.

Expert Insights from Mechanics: Troubleshooting and Repair

While the injector pump is complex, troubleshooting common issues is often possible with a little know-how. Experienced mechanics share valuable insights:

- Start by listening: A clicking sound during cranking might indicate a worn plunger or a problem with the delivery valve.

- Check the fuel pressure: Using a pressure gauge connected to the fuel line, you can verify if the pump is delivering adequate pressure.

- Inspect the injectors: Look for signs of clogging or leakage. You might need specialized tools for this, so seeking professional help is often the wisest choice.

3 Cylinder Yanmar Injector Pump Diagram

The Value of Knowledge: Empowering Your Yanmar Engine

Understanding the Yanmar injector pump diagram is more than just a technical exercise; it’s a gateway to a deeper understanding of your engine’s operation and how to keep it running smoothly. By mastering the basics, you’ll be equipped to:

- Identify potential problems.

- Troubleshoot common issues with confidence.

- Make informed decisions about maintenance and repairs.

With knowledge as your guide, you can confidently navigate the world of your 3-cylinder Yanmar engine, ensuring its longevity and optimal performance for years to come.

![Cyclomancy – The Secret of Psychic Power Control [PDF] Cyclomancy – The Secret of Psychic Power Control [PDF]](https://i3.wp.com/i.ebayimg.com/images/g/2OEAAOSwxehiulu5/s-l1600.jpg?w=740&resize=740,414&ssl=1)