Have you ever experienced the frustration of a malfunctioning air compressor, leaving you stranded with a project half-finished? That was my experience recently. While working on a DIY project, my Ingersoll Rand compressor suddenly shut down, displaying an unfamiliar error code. I was completely lost, unsure where to start troubleshooting. It wasn’t until I stumbled upon a detailed guide on fault codes that I was able to identify the problem and quickly get back to work. This experience highlighted the importance of understanding compressor fault codes, which can save you time, money, and frustration.

Image: www.inf-inet.com

This guide will provide you with an in-depth understanding of Ingersoll Rand compressor fault codes, equipping you with the knowledge to diagnose and resolve common issues. We’ll delve into the intricacies of interpreting these codes, exploring their meaning, and providing practical tips for troubleshooting. By the end of this article, you’ll be confidently able to approach any compressor malfunction, minimizing downtime and maximizing efficiency.

Decoding the Mystery Behind Ingersoll Rand Compressor Fault Codes

Ingersoll Rand compressors are renowned for their reliability and durability, but even the most robust machines can experience occasional malfunctions. These issues often manifest as error codes, which can be perplexing to the untrained eye. However, these codes are not random; they represent specific events or conditions within the compressor’s system. Understanding these codes is essential for pinpointing the root cause of a problem and taking appropriate action.

Ingersoll Rand compressor fault codes typically consist of a combination of letters and numbers, each signifying a specific component or function. For example, “E1” might indicate a problem with the motor, while “F3” could signal a pressure sensor issue. These codes are often displayed on a digital panel or through a series of LED lights, depending on the compressor model. Many models also include built-in diagnostic tools that allow for further investigation.

Understanding The Language of Your Compressor

Interpreting Fault Codes: A Step-by-Step Guide

Interpreting Ingersoll Rand compressor fault codes requires a methodical approach. Here’s a step-by-step guide to help you decipher the meaning behind those cryptic codes:

- Locate the Fault Code Display: Identify the location of the fault code display on your compressor. It’s often on the control panel or a small digital display near the motor.

- Record the Fault Code: Carefully note down the exact code displayed. This is crucial for referencing the code in the user manual or online resources.

- Consult the User Manual: Refer to the user manual that came with your compressor. The manual will usually include a detailed table mapping fault codes to their corresponding meaning and recommended actions.

- Seek Online Resources: If the manual doesn’t provide adequate information or if you’re dealing with a more complex code, turn to online resources. Many online forums and websites provide extensive databases of Ingersoll Rand fault codes and their explanations.

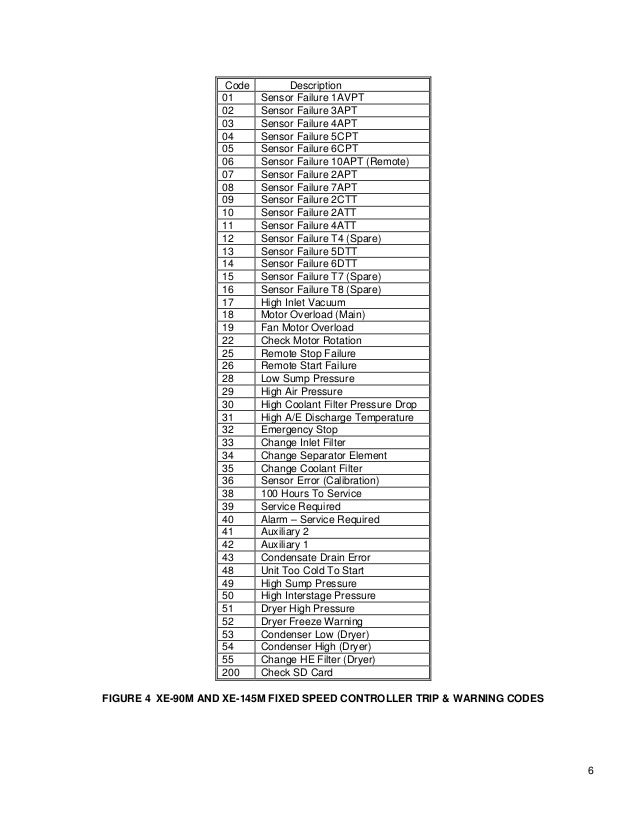

Image: manualzz.com

Common Ingersoll Rand Compressor Fault Codes and Their Meanings

| Code | Description |

|---|---|

| E1 | Motor overload or failure |

| E2 | High temperature sensor fault |

| E3 | Low oil pressure |

| F1 | Pressure switch fault |

| F2 | Unloading valve malfunction |

This table provides a starting point for understanding common Ingersoll Rand compressor fault codes. It’s essential to remember that the actual codes and their meanings can vary based on the specific compressor model. Therefore, always refer to the model-specific user manual for accurate interpretations.

Troubleshooting Techniques for Resolving Compressor Issues

Once you’ve successfully identified the fault code and its meaning, you can move on to troubleshooting. Here are some general techniques that can be applied to address common compressor issues:

- Reset the Compressor: In some cases, a simple reset can resolve the problem. Disconnect the compressor from power, wait a few minutes, and then reconnect it. This allows the system to reset and potentially clear the fault.

- Check Electrical Connections: Ensure all electrical connections to the compressor are secure and free from corrosion. Loose or faulty connections can cause various malfunctions.

- Inspect the Motor: If the fault code indicates a motor issue, visually inspect the motor for signs of damage or overheating. Listen for any unusual sounds while the motor is running.

- Examine Pressure Sensors: Pressure sensors are crucial for regulating the compressor’s operation. Carefully examine any pressure sensors for signs of damage, contamination, or improper alignment.

- Verify Oil Level: Many Ingersoll Rand compressors rely on oil for lubrication and cooling. Check the oil level and add oil if necessary, following the manufacturer’s recommendations.

It’s crucial to approach troubleshooting with caution. If you’re uncomfortable working with electrical systems or mechanical components, seek assistance from a qualified technician. Improper handling can result in further damage or injury.

Trends and Developments in Ingersoll Rand Compressor Fault Codes

The world of compressor technology is constantly evolving. Ingersoll Rand, known for its innovation, is continually introducing new features and functionalities. As technology advances, so do the nature and complexity of fault codes. Here are some trends to keep in mind:

- Enhanced Diagnostics: Modern Ingersoll Rand compressors are equipped with advanced diagnostic features, providing more detailed information about errors and facilitating quicker troubleshooting. This includes real-time monitoring, fault logging, and even remote accessibility for service technicians.

- Predictive Maintenance: Ingersoll Rand is incorporating predictive maintenance capabilities into its compressor models. By analyzing data patterns, these systems can anticipate potential failures and alert operators in advance, minimizing downtime and maximizing operational efficiency.

- Connectivity: The Internet of Things (IoT) is playing a significant role in compressor technology. Ingersoll Rand is integrating smart features into its compressors, enabling remote access, data monitoring, and automatic fault reporting. This allows for proactive maintenance and streamlined troubleshooting, reducing costs and improving overall operational efficiency.

Expert Tips for Navigating Ingersoll Rand Compressor Fault Codes

Based on my experience, here are some actionable tips that can help you navigate Ingersoll Rand compressor fault codes effectively:

- Thorough Documentation: Keep detailed records of all encountered fault codes, the time they occur, and the steps you took to resolve them. This documentation helps track recurring issues and provides valuable insights for future troubleshooting efforts.

- Regular Maintenance: Follow the manufacturer’s recommended maintenance schedule for your Ingersoll Rand compressor. Regular maintenance, such as oil changes, air filter replacement, and pressure checks, helps prevent common issues and extends the life of your equipment.

- Invest in Training: If you frequently work with Ingersoll Rand compressors, investing in formal training can greatly enhance your troubleshooting skills. Training courses can familiarize you with advanced diagnostic methods, common failure points, and best practices for maintenance.

- Seek Professional Help: Don’t hesitate to contact a qualified technician or Ingersoll Rand support if you encounter a complex fault code or are unsure how to proceed. Their expertise can help prevent further damage and ensure your compressor is repaired correctly.

By following these tips, you can avoid common pitfalls, optimize your troubleshooting process, and ensure the longevity of your Ingersoll Rand compressor. Remember, proactive maintenance and responsible troubleshooting are key to maximizing the efficiency and reliability of your equipment.

Frequently Asked Questions

Q: How do I access the fault code manual for my specific Ingersoll Rand compressor model?

A: The fault code manual is usually included with your compressor’s documentation. If you’ve misplaced the manual, you can often find a digital version on Ingersoll Rand’s website or by contacting their customer support. Specify your compressor model number for accurate information.

Q: Are there any universal fault codes that apply to all Ingersoll Rand compressor models?

A: While some codes may appear across different models, the specific meaning and troubleshooting steps can vary. Always refer to the user manual for your specific model to ensure accurate interpretation.

Q: What should I do if I can’t find the cause of a fault code after troubleshooting?

A: If you’ve exhausted all troubleshooting options and are unable to resolve the issue, it’s best to seek professional help from a qualified technician. They have the specialized equipment and expertise to diagnose and repair complex compressor problems.

Ingersoll Rand Compressor Fault Codes Pdf

Conclusion

Understanding Ingersoll Rand compressor fault codes is essential for both owners and maintenance professionals. By mastering the language of your compressor and utilizing various troubleshooting techniques, you can streamline maintenance, minimize downtime, and ensure optimal performance. Remember to follow the manufacturer’s recommendations, practice regular maintenance, and don’t hesitate to seek expert assistance when necessary.

Are you familiar with Ingersoll Rand compressor fault codes? Share your experiences in the comments below!

![Cyclomancy – The Secret of Psychic Power Control [PDF] Cyclomancy – The Secret of Psychic Power Control [PDF]](https://i3.wp.com/i.ebayimg.com/images/g/2OEAAOSwxehiulu5/s-l1600.jpg?w=740&resize=740,414&ssl=1)