Imagine a world without motion. No cars rushing down highways, no whirring fans keeping us cool, and no spinning turbines generating electricity. It’s a world devoid of the very essence of progress and innovation. At the heart of this motion lies a fundamental principle: the speed of a motor, a critical factor that determines how efficiently and effectively a machine can perform its tasks. But what exactly dictates this speed, and how can we understand it through a simple formula?

Image: www.9icnet.jp

The speed of a motor, often referred to as its rotational speed or RPM (revolutions per minute), is a measure of how quickly it turns. This speed is a vital parameter, influencing everything from the power output of a machine to the precision of its operations. Understanding the formula for motor speed unlocks a world of possibilities, allowing us to calculate, predict, and even manipulate the performance of various motors in real-world applications.

The Fundamental Equation: Unraveling the Relationship

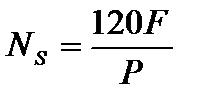

The formula for motor speed is a deceptively simple yet powerful equation that forms the bedrock of understanding motor performance. It states that:

Speed (RPM) = (Frequency (Hz) * 60) / Number of Poles

This equation reveals a profound relationship between several key factors:

- Frequency (Hz): This represents the frequency of the alternating current (AC) supply that powers the motor. It dictates the rate at which the magnetic field in the motor changes, influencing the speed of rotation.

- Number of Poles: The number of poles in the motor determines the number of times the magnetic field reverses in one complete rotation. A higher number of poles translates to a lower speed for a given frequency.

Dissecting the Equation: A Closer Look

Let’s delve deeper into the meaning of each component in the speed formula:

Image: www.electricalengineeringtoolbox.com

Frequency: The Heartbeat of the Motor

Frequency, measured in Hertz (Hz), refers to the number of cycles per second of the alternating current that powers the motor. The higher the frequency, the faster the magnetic field inside the motor changes. This change in the magnetic field induces a force that causes the motor to rotate.

In most industrial applications, motors operate on a standard frequency of 50 Hz or 60 Hz. However, new technologies like variable frequency drives (VFDs) allow us to precisely control the frequency and, consequently, the speed of the motor. This flexibility is crucial for optimizing motor performance, especially in tasks that require varying speeds.

Number of Poles: Dictating the Rotation

The number of poles in a motor defines the number of magnetic field reversals that occur during each complete rotation. A two-pole motor has one magnetic field reversal per rotation, while a four-pole motor has two reversals. This relationship means that a higher number of poles results in a smaller speed for a given frequency.

The number of poles is a design parameter typically determined during motor manufacturing. It’s crucial in adapting the motor to specific applications. For instance, a high-speed motor used in a centrifugal pump might have fewer poles, while a low-speed motor designed for heavy-duty lifting applications could feature a higher number of poles.

Putting it to Practice: Real-World Implications

The formula for motor speed isn’t just a theoretical concept, but a practical tool that guides engineers and technicians in numerous real-world scenarios. Here are a few examples of how this formula is applied:

1. Designing Motors for Specific Applications:

Engineers use the motor speed formula to create motors that match the requirements of specific applications. They carefully adjust the number of poles in the design to achieve the desired speed for a particular task. This ensures that the motor delivers optimal performance, whether it’s powering a conveyor belt, turning a machine spindle, or driving a pump.

2. Controlling Motor Speed with Variable Frequency Drives (VFDs):

Modern industrial applications often require precise control over motor speed. This is where variable frequency drives (VFDs) come into play. VFDs electronically adjust the frequency of the power supply to the motor, effectively manipulating its speed. By changing the frequency, we can adjust the motor’s speed according to the demands of the application. This control is essential in applications where speed needs to be varied dynamically, such as in elevators, conveyor systems, and robotic arms.

3. Troubleshooting Motor Performance Issues:

If a motor isn’t performing as expected, the motor speed formula becomes an invaluable diagnostic tool. By analyzing the motor’s speed, frequency, and the number of poles, we can identify potential problems. For instance, if the motor is operating at a lower speed than expected, this might indicate a frequency issue, a faulty motor winding, or a problem with the motor’s load.

The Future of Motor Speed: Advancements and Innovations

The realm of motor technology continues to evolve, with new innovations constantly pushing its boundaries. Here are some exciting trends that are shaping the future of motor speed:

1. High-Efficiency Motors:

Energy efficiency is a crucial concern in today’s world. High-efficiency motors are designed to minimize energy consumption and maximize output. These motors often feature optimized magnetic fields, reduced losses in their windings, and improved materials. The formula for motor speed is instrumental in guiding the development of these efficient designs.

2. Brushless DC Motors:

Brushless DC motors offer several advantages over traditional motors, including high efficiency, longer lifespan, and quieter operation. The formula for motor speed remains relevant in understanding the performance of these motors, as it establishes the relationship between frequency, number of poles, and speed. The advent of advanced control systems and sensorless technology has further enhanced the control and performance of these motors.

3. Smart Motors:

Smart motors are equipped with built-in sensors and communication capabilities that allow them to monitor their own performance and communicate data to external systems. This data can be used to optimize motor operation, prevent failures, and enhance overall system efficiency. The formula for motor speed plays a crucial role in interpreting this data and making informed decisions about motor control.

Formula For Speed Of A Motor

Conclusion: Embracing the Power of Motion

The formula for motor speed is a powerful tool that unlocks a deeper understanding of the fascinating world of motion. By comprehending the intricate relationship between frequency, number of poles, and speed, we gain the ability to predict, control, and optimize the performance of motors. As we continue to innovate and push the boundaries of motor technology, this fundamental formula will remain a cornerstone, guiding us towards a future filled with efficient, precise, and intelligent motion.

From the small motors in everyday appliances to the powerful engines driving our vehicles, the ability to calculate and control motor speed is crucial. By diving deeper into this subject, we not only uncover the scientific principles behind motion but also gain valuable insights into a world where efficiency, control, and innovation are intertwined.

![Cyclomancy – The Secret of Psychic Power Control [PDF] Cyclomancy – The Secret of Psychic Power Control [PDF]](https://i3.wp.com/i.ebayimg.com/images/g/2OEAAOSwxehiulu5/s-l1600.jpg?w=740&resize=740,414&ssl=1)