Have you ever stopped to think about the journey of a humble cardboard box? From its humble beginnings as raw materials to its final form, protecting and delivering treasures across the globe, it’s a fascinating process. Today, we’re delving into the world of corrugated box manufacturing, unveiling the secrets behind this ubiquitous packaging solution. Get ready to embark on a visual adventure through the comprehensive flow diagram of a corrugated box’s creation – a journey that’s both intricate and essential to our modern world.

Image: www.slideshare.net

Imagine a world without cardboard boxes. No more secure packaging for your online purchases, no more protective containers for fragile goods, and no more efficient transportation of countless products. It’s hard to fathom, isn’t it? The truth is, corrugated boxes are the unsung heroes of our supply chains, silently ensuring the safe and efficient delivery of countless products to our doorsteps. But how do these seemingly simple structures come to life? Let’s dive into the intricate world of corrugated box manufacturing, guided by a visual flow diagram that unveils each step of this remarkable process.

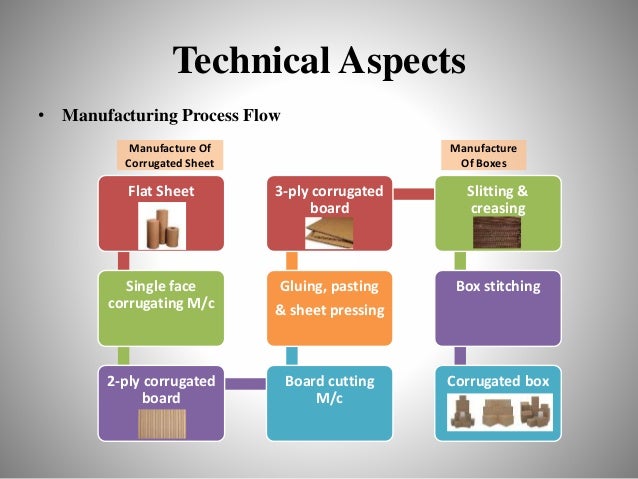

From Raw Materials to Ready-to-Ship: Breaking Down the Flow Diagram

The process of creating a corrugated box begins with the very essence of its existence: raw materials. It all starts with pulp, a fibrous mixture obtained from wood or recycled paper. This pulp undergoes various treatments to ensure the strength and consistency needed for the box’s durability. The flow diagram below outlines the major stages, giving you a comprehensive visual understanding of the journey:

Step 1: Pulp Preparation:

- Visual: Imagine a swirling vortex of pulpy fibers.

- Process: Recycled paper or wood is carefully mixed with water to create a slurry. This process involves removing impurities like ink and other contaminants, leaving behind a refined pulp ready for the next step.

Step 2: Corrugating the Board:

- Visual: Envision thin sheets of paper being transformed into wavy, sturdy layers.

- Process: The pulp is fed into a machine that creates the distinctive corrugated pattern. Waves of flute, the wavy inner layer, are pressed onto a flat liner board, resulting in a durable yet lightweight structure.

Step 3: Combining Layers:

- Visual: Picture layers of corrugated board being expertly aligned and bonded together.

- Process: Multiple layers of corrugated board are stacked and bonded using specialized glue. This layered structure creates the iconic three-layered corrugated board: a flat liner board, a layer of flute, and another liner board.

Step 4: Cutting and Shaping:

- Visual: Imagine a giant cookie cutter diligently shaping the raw corrugated board into precise shapes.

- Process: The corrugated board is precisely cut and shaped, ensuring each box aligns with the specific dimensions and desired design. Specialized machinery, often featuring laser cutters for extreme accuracy, takes center stage in this crucial step.

Step 5: Printing and Finishing:

- Visual: Envision boxes adorned with vibrant colors, logos, and marketing messages.

- Process: Printing presses apply intricate designs, logos, and branding information directly onto the corrugated board. The boxes may undergo further finishing touches like laminating, spot varnishing, or die-cutting to enhance their visual appeal and functionality.

Step 6: Folding and Gluing:

- Visual: Picture boxes gracefully transforming from flat sheets into their three-dimensional forms.

- Process: The cut and printed corrugated boards are folded and glued, transforming them into the familiar shape of boxes. Specialized machinery meticulously folds and secures the flaps and edges, ensuring a robust and finished product.

Step 7: Quality Control and Packaging:

- Visual: Imagine a team of skilled inspectors carefully scrutinizing each box, ensuring it meets the highest standards.

- Process: A careful inspection process ensures that every box adheres to strict quality guidelines. Any imperfections are flagged, and the quality control measures guarantee the delivery of flawless and functional packaging solutions.

Step 8: Shipping and Distribution:

- Visual: Envision a fleet of trucks transporting boxes brimming with products, ready to conquer the world.

- Process: The finished boxes are carefully stacked, packed, and shipped to their respective destinations – ready to protect and transport an array of goods, big and small.

Unveiling the Secrets Behind Corrugated Boxes: Insights from the Industry

The corrugated box manufacturing process, though seemingly simple at first glance, is a marvel of engineering and coordination. Each step in the process contributes to the box’s ultimate strength, durability, and functionality. Here are key insights from industry experts that shed light on the nuances of this fascinating process:

- Sustainability is key: The corrugated box industry is making immense strides in sustainability practices. Recycling plays a critical role. The use of recycled paper in pulp production significantly reduces the environmental footprint of this industry.

- Customization reigns supreme: Corrugated boxes are no longer just basic containers. With advancements in printing, finishing techniques, and design, these boxes can be tailored to specific product needs, featuring vibrant visuals, custom shapes, and even inserts for enhanced protection.

- Automation is on the rise: The corrugated box industry is rapidly embracing automation, using robotics and AI-powered systems to streamline processes, enhance efficiency, and ensure consistent product quality.

Image: epackagingsolution.com

Flow Diagram Corrugated Box Manufacturing Process Flow Chart

The Power of Corrugated Boxes: A Call to Action

The next time you see a cardboard box, don’t just see a plain container. See it as a testament to human ingenuity, a marvel of manufacturing, and a vital part of our modern world. Corrugated boxes are more than just packaging; they are the backbone of global trade, ensuring the safe and efficient delivery of goods to our doorsteps.

From the pulp’s initial transformation to the box’s final journey, each step in the flow diagram represents a carefully orchestrated process, driven by innovation and environmental consciousness. As consumers, we can embrace the sustainability of this industry by recycling cardboard boxes, making conscious choices about packaging, and supporting brands that prioritize environmental responsibility in their packaging practices.

We invite you to share your own experiences with corrugated boxes. Have you ever been impressed by a unique box design? Or perhaps you’ve witnessed the positive impact of recycled cardboard in your community? Let us know in the comments below! Let’s continue the conversation about the power of these seemingly simple yet essential packaging solutions.

![Cyclomancy – The Secret of Psychic Power Control [PDF] Cyclomancy – The Secret of Psychic Power Control [PDF]](https://i3.wp.com/i.ebayimg.com/images/g/2OEAAOSwxehiulu5/s-l1600.jpg?w=740&resize=740,414&ssl=1)